Technological utilization of photocatalytic oxidation for cleaning air and water is an exciting and recently developed technology. This technique forms the basis for purification technology commercialized by many different companies and studied by many different researchers. These technologies process pollutants in a photoreactor that utilizes photons of light to initiate a reaction which oxidizes and destroys organic pollutants in water and air. Photoreactor-based air purifiers are typically of Photocatalytic Oxidation (PCO) type, or Photo Electrochemical Oxidation (PECO)—the proprietary technology contained in the Molekule air purifier. The following is a breakdown of how the PECO air purifier is different from all the other air purifiers that take advantage of the principle of photon-activated oxidation of pollutants.

What is photocatalytic oxidation?

Photocatalytic oxidation purification is a process that involves a light-activated catalyst reacting with organic pollutants to oxidize them. Essentially, these pollutants undergo a chemical reaction that transforms them into non-toxic substances. Since the 1990s, hundreds of papers have been published on the possibility of using this process to clean the air and water of toxic pollutants. There is a lot of interest as it enters the mainstream and more companies bring products to market that feature such a groundbreaking technology.

Photocatalytic process in PECO vs. PCO air purifiers

One of Molekule’s founders, Dr. Yogi Goswami, was instrumental in the development of using a photocatalytic process to oxidize pollutants in the air and water around 1991. His quest for a more perfect photoreactor-based technology and his research over the last two decades finally led to PECO for air purification.

How does PECO compare with PCO? Photo Electrochemical Oxidation (PECO) is an innovative photon-based air purification process which is orders of magnitude faster and more efficient than Photocatalytic Oxidation (PCO) type air purifier technology. PECO is commercialized as the technology employed in Molekule air purifiers.

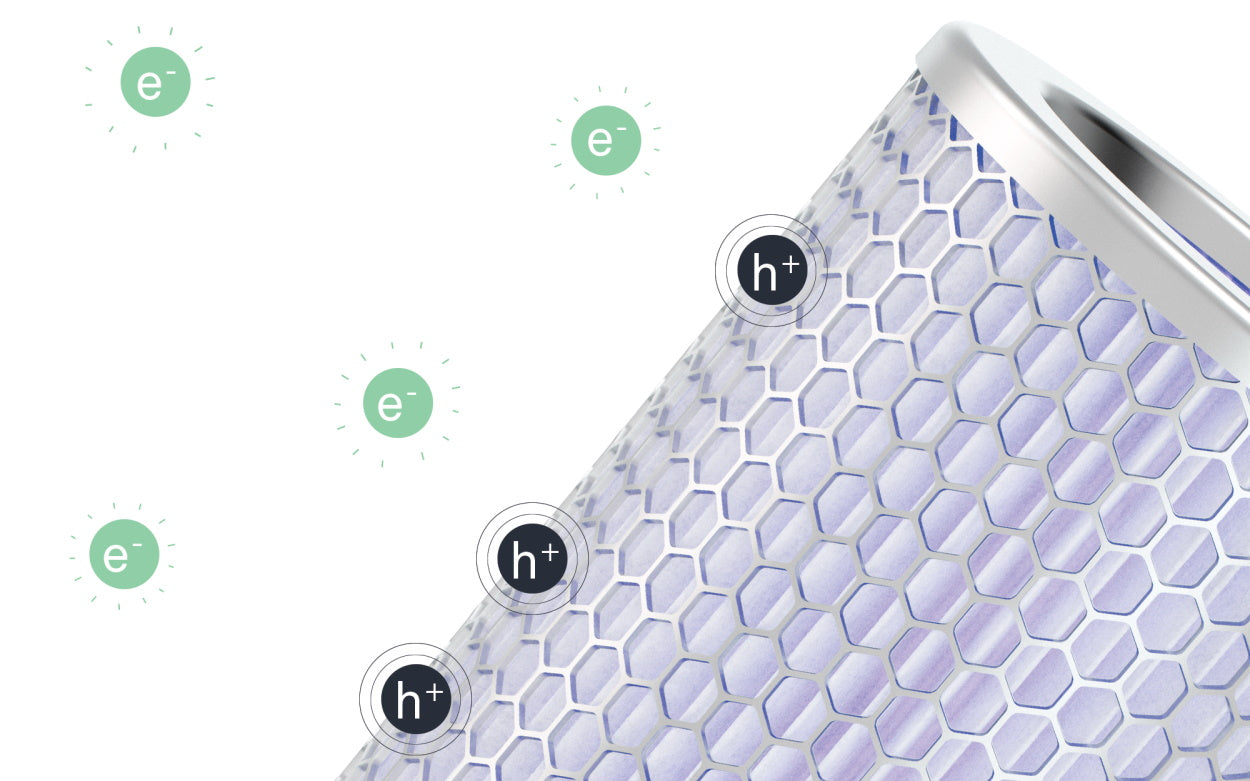

Both PCO and PECO use photons of sufficient energy to initiate a chain of reactions by liberating electrons (negative charge) and forming holes (positive charge). However, since negative electrons like to combine with positive holes, very few holes remain available for reaction in a PCO process, which makes the process inefficient. On the other hand, PECO keeps electrons and holes separated which results in extremely fast and complete reactions with no byproducts other than what is supposed to be in the air. Simply put, PECO uses the photons of light as efficiently as possible to completely oxidize the organic pollutants in air.

Here are the main components used in any photocatalytic process:

Photocatalyst. A photocatalyst is a substance that mediates a chemical reaction on its surface when activated by light. In both PECO and PCO air purifiers, this chemical reaction is employed to break down pollutants. PECO uses a proprietary catalyst that has been engineered over two decades to lend the greatest efficiency to the process.

Free Radicals and Reactive Oxygen Species. All photoreactor processes use photons of light to free electrons from the surface of the catalyst leaving positive holes in the catalyst where electrons used to be. Hydroxyl ions (OH-) form naturally from water vapor in the air and have a negative charge. They react with the positive holes on the catalyst surface by inserting an electron in the hole to make the ions electrically neutral again and become hydroxyl free radicals. Hydroxyl free radicals are among the most potent oxidizers, and can oxidize even the toughest organic molecules with the help of oxygen from the air. The end result of oxidation is generally the conversion of organic compounds into carbon dioxide, water and other trace gases, similar to being incinerated but without the heat.

The major difference between the PCO and the PECO processes is the consideration of the negative electrons and positive holes after their generation by the photons. Since negative electrons tend to quickly recombine with the positive holes, fewer holes are available to react in the case of the catalysts used in PCO, which results in low quantum efficiency of the PCO photoreactor. On the other hand, the PECO process binds the free electrons and keeps them separated from the positive holes long enough for the holes to form the hydroxyl free radicals.

This fundamental difference between the two processes has major consequences. Due to the recombination of electrons and holes, the PCO process can utilize only a small fraction of the photons, which makes the overall process inefficient. A potential danger of the inefficient process is that some systems may yield toxic oxidation byproducts such as formaldehyde due to an incomplete reaction. PECO on the other hand, has a quantum efficiency many orders of magnitude higher than that of the PCO process, which makes the PECO oxidation process extremely fast resulting in complete oxidation with no byproducts.

Finally, hydroxyl radicals not only react easily with organic pollutants, but they are also very unstable in the air and are quickly reabsorbed to form water, so there is no possibility they would make it out of the device.

UV light. Light is used in the photocatalytic process to excite and activate the catalyst to begin the chemical reaction to break down pollutants. PECO air purifiers use low energy UV-A light to begin the reaction. The most common type of light to use for PCO air purifiers is a very energetic band of light, UV-C, to initiate the reaction. However, UV-C is also known to produce ozone, which is also a potent oxidizer and toxic to living things. Caution should always be used to ensure no people, pets, or houseplants are exposed to elevated levels of ozone.

Safety and effectiveness of PECO vs. PCO air purifiers

When considering a photocatalytic system, it is very important to be sure it is efficient enough to not produce byproducts. There are several factors that influence the efficiency of a PCO device. Engineers have to consider how much light is falling on the catalyst, what types and concentrations of pollutants the device is expected to deal with, the flow of air through the device, moisture levels in the air, properties of the specific catalyst used, and how the device itself is configured.

There are a few ways a consumer can figure out if a PCO system is safe and effective.

No ozone. The California Air Resources Board (CARB) does not allow air purifiers to be sold in California that produce unsafe levels of ozone, so make sure the PCO system is listed as CARB compliant on the CARB website and on the manufacturer’s website as well. The Molekule PECO air purifier has been certified as CARB compliant and independently tested by Intertek Laboratories to not produce any ozone—in fact, Molekule’s PECO technology has been proven to reduce ozone levels.

Long enough dwell time. A pollutant has to spend enough time on or very close to the catalyst to be exposed to enough oxidative species to be completely oxidized, which is called the pollutant’s dwell time. If the system doesn’t seem to capture pollutants and hold them in place near the catalyst on the first pass, then it might not be completely destroying them. For example, if the pollutants are following an air path that doesn’t carry them directly onto the catalyst they can easily end up in a region with a lower concentration of radicals. This is particularly problematic with simple organic molecules, such as those found in natural or synthetic fragrance. If partially oxidized, the nice smell of flowers can end up converted into toxic formaldehyde and acetaldehyde. This is a concern for PCO air purifiers. The PECO technology has been tested to not produce any harmful byproducts.

Plenty of research. This is one of the most important aspects to pay attention to when selecting a photocatalytic air purifier. Look for tests done by laboratory companies external to the manufacturer and see how well it can destroy pollutants like VOCs and microbes. If there is no research available, then it’s possible the unit is inefficient at best or totally ineffective at worst. The PECO technology was developed over a period of 20 years, and took multiple iterations to come from its beginnings as a PCO system to one that is highly efficient and effective in removing pollutants from the air without generating harmful side-products.

PECO vs. PCO in tackling pollutants

Microbes. One of the photocatalytic process’s key differentiators is its ability to sterilize microorganisms, preventing them from growing or infecting. Airborne viruses, bacteria, fungal spores, and fungal fragments adhere to the catalyst where they are subjected to the oxidative species generated by the photocatalytic process. Microbial cell walls are destroyed through interaction with the free radicals generated on the light activated catalyst surface. Toxins and allergic substances are also oxidized in this process, so any components of the organism that may cause health problems are also safely destroyed. Toxins are invisibly present in any fragment of a microbe. The oxidative effect of a PCO device is in theory sufficient to destroy these toxins, but little research has been done on different PCO technologies on the market. Molekule has conducted extensive research on PECO’s ability to sterilize mold spores and a variety of other microbes. More than just sterilization, PECO converts the cells of the microbes to benign byproducts, such as carbon dioxide and water.

Allergens. In addition to microbes, free-floating particles called allergens can also be harmful by causing allergic reactions that are at best uncomfortable and at worst impact your productivity and health. The oxidative effect of photocatalysis can break down allergens so they don’t elicit a reaction.

VOCs. Volatile organic compounds can be dangerous to your health, particularly if they come from industrial products like paint, furniture, or building materials. VOCs are vulnerable to oxidation by the oxidative species generated by photocatalysis. Some research has shown that PCO may convert certain VOCs into toxic byproducts such as formaldehyde and acetaldehyde. In third party testing done on PECO, formaldehyde was destroyed along with other VOCs.

Ozone. Many PCO devices use UV-C light to power the catalytic reaction. UV-C light is well-known for its ability to convert oxygen to ozone. In fact, the ozone layer in the upper atmosphere is made from oxygen exposed to UV-C light from the sun. PECO uses a different band of UV light called UV-A, which is the same light used in tanning bed bulbs and in the “black light” bulbs that make posters glow fluorescently. PECO actually breaks down ozone so it becomes oxygen again.

PECO is a fundamental scientific innovation over PCO. Most PCO devices fail to show that their particular device is optimized to take full advantage of the photocatalytic process. It is important to note the above considerations when comparing the two technologies and choose the safest and most effective air purifier for your home.